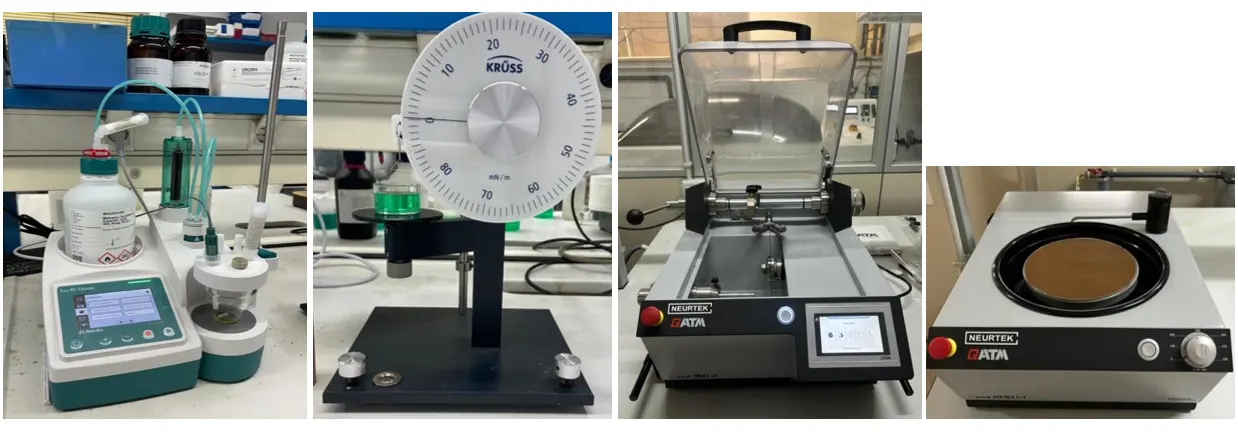

Elhco has incorporated new equipment to perform tests in both chemical and metallographic laboratories. The recently acquired equipment includes:

- Karl-Fischer Titrator: This equipment is used for determining the water content in organic reagents, according to ISO 760 standards, allowing us to control the validity of our products in the liquid penetrant inspection facility.

- Tensiometer: This equipment will be used to measure the surface tension of the different plating baths used at Elhco. It performs quick, simple, and accurate measurements of surfactant solutions and solvents.

- Sectioning Machine: Metallographic cutting is the first step in preparing samples for metallographic analysis. With this equipment, we can perform sample cutting quickly and accurately.

- Polishing machine: Its purpose is to remove scratches and obtain a specular surface on the sample contained in the mount made during embedding, before analysis under the microscope.

This way, Elhco will be able to carry out new tests independently and obtain results more quickly, allowing us to streamline and improve our internal quality control processes. Furthermore, these pieces of equipment will be highly useful for the various R&D projects in which Elhco is currently involved and for future projects to undertake.