PENETRATING LIQUIDS

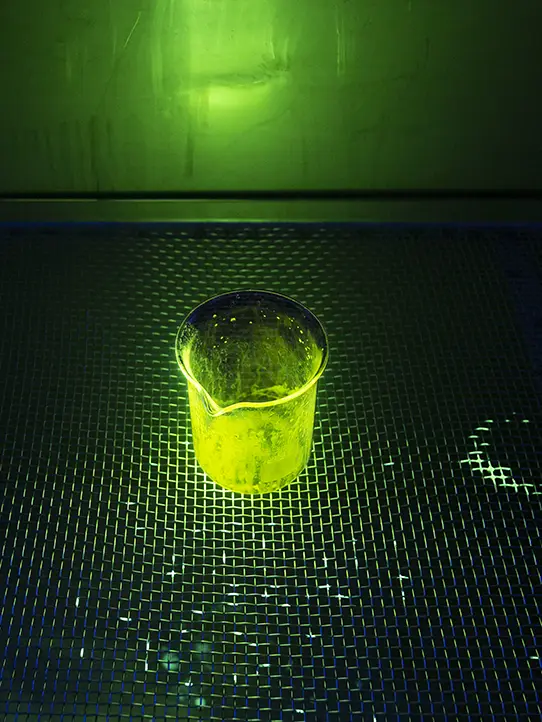

It is a non-destructive test in which possible cracks and/or surface pores present in the material (commonly aluminium and stainless steel) are analysed.

The process consists of submerging the pieces in a liquid (fluorescent in our case) that has great penetration in pores and cracks.

After the corresponding washing procedure, the pieces are subjected to a revealing powder that fixes the fluorescent liquid so that it does not come out of the crack. Thus, possible indications can be observed in the inspection cabin with ultraviolet light making possible cracks and/or pores shine.

MAGNETIC PARTICLES

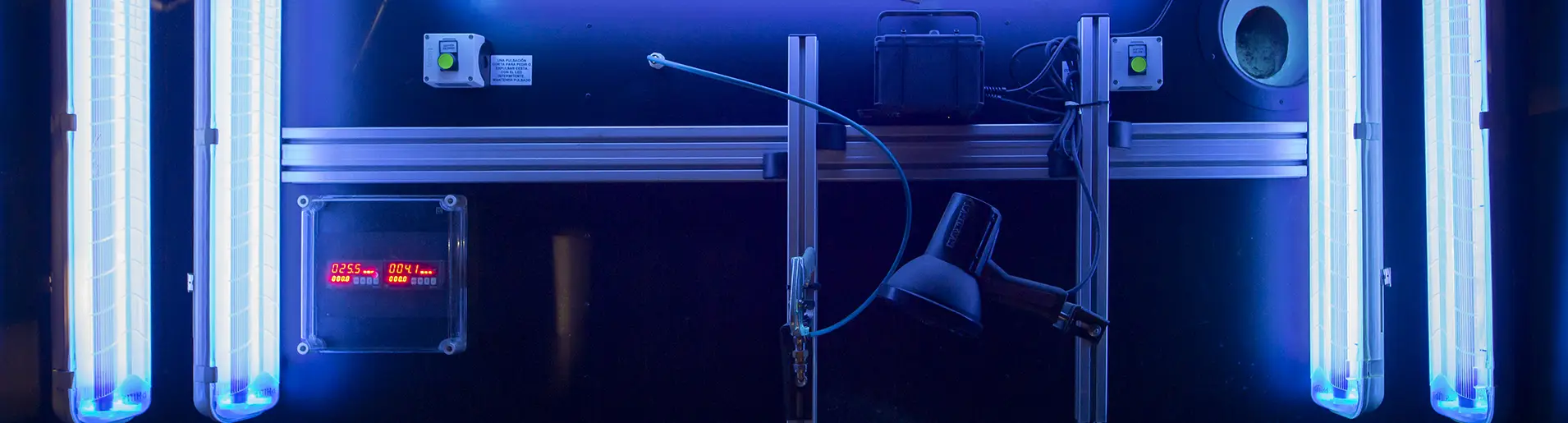

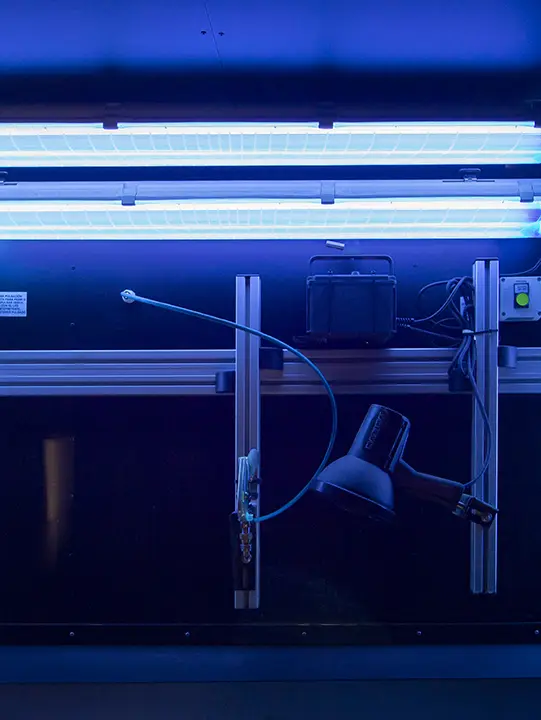

It is a non-destructive test in which possible cracks and/or surface pores present in the material (commonly steel and/or magnetic/magnetisable materials) are analysed.

The piece is magnetised on a work table that has a fluid with suspended fluorescent magnetic particles. This liquid is passed over the piece and where there is a pore or groove, the particles are retained.

Subsequently, the piece is analysed under ultraviolet light, if there are any pores or grooves, a fluorescent emission is observed.