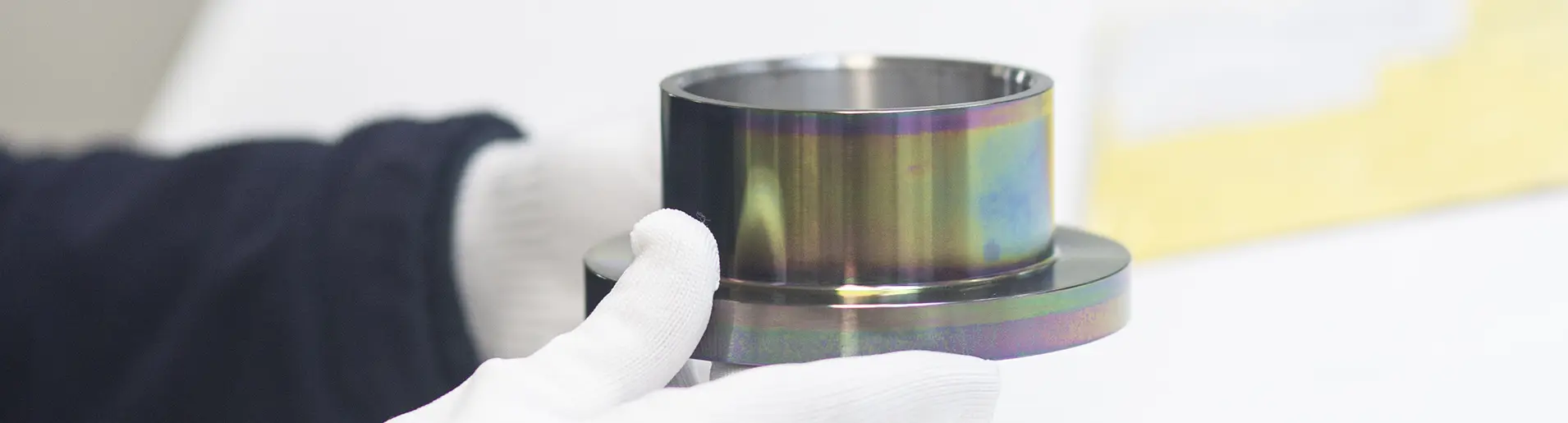

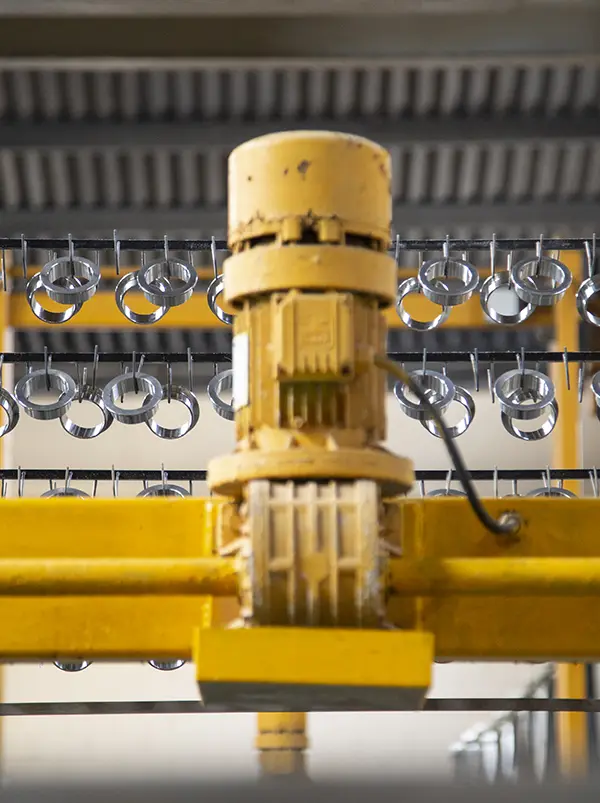

ZINC-NICKEL COATING

The Zn-Ni electrolytic coating consists of the deposition of a zinc and nickel alloy, with a nickel concentration of between 6–16%.

It is a medium-hard coating, being able to reach 450 HV. This coating provides high resistance to corrosion (more than 750 hours in a salt spray chamber) with thicknesses between 10 and 18 microns.

Another of its purposes is to avoid the galvanic cell effect when steel and aluminium have to be assembled together, thus avoiding accelerated oxidation of aluminium.

It is also used as an etching coat for the application of primer and paint.