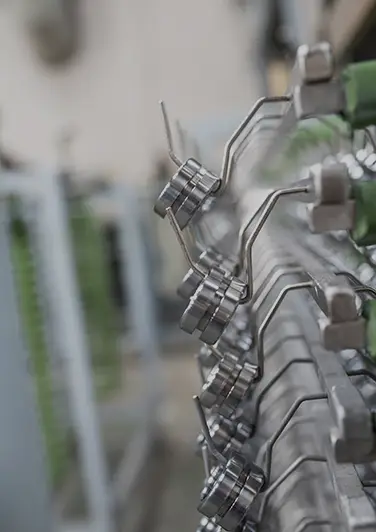

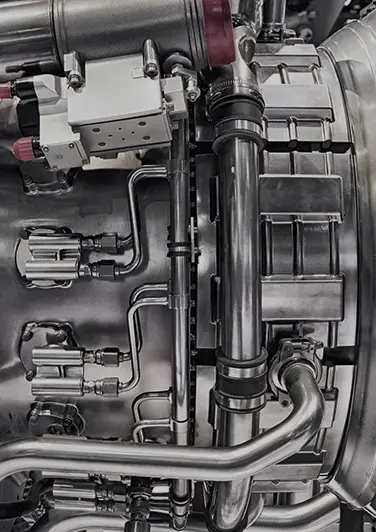

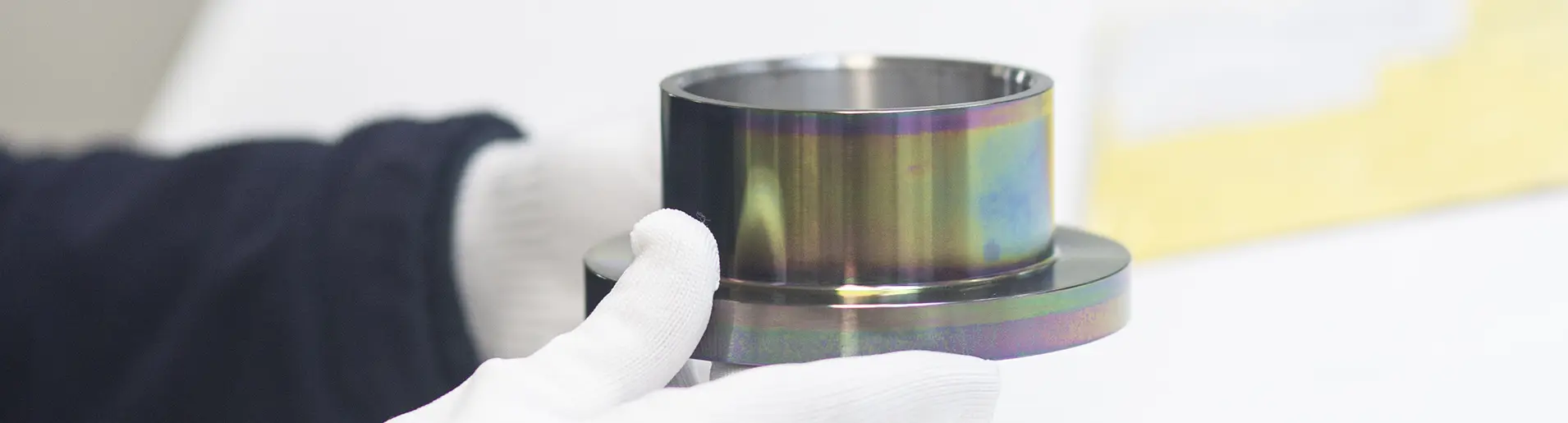

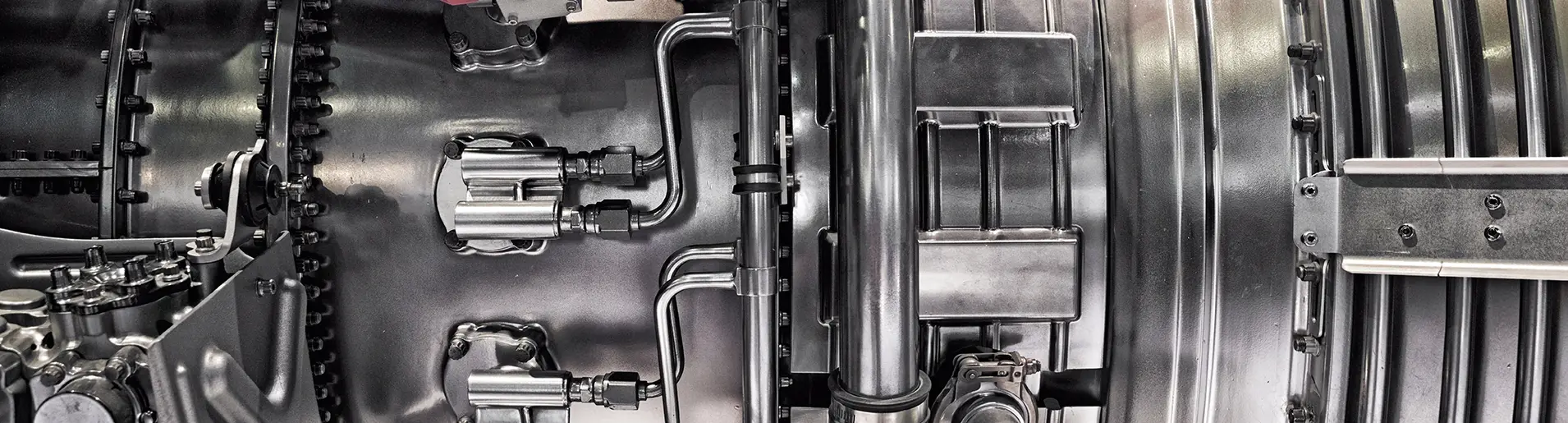

Specialists in metallic surface finishes and coating of metallic parts. We work with different industrial specifications, if you do not find the one you are looking for in this section, contact us.

METALLIC SURFACE FINISHES

Coating of metal parts

These are the main processes we carry out at Elhco

Specialists in technical surface treatments and metal coatings: electroless nickel, electroless nickel-teflon, zinc-nickel, electrolytic nickel, gold, silver and tin. Part preparation treatments and industrial painting.

CONTACT DETAILS

- Ctra. C-155 (Sabadell – Granollers) Km. 11.4

Polígon La Serra- 08185 Lliçà de Vall

Barcelona - (+34) 93 843 62 17

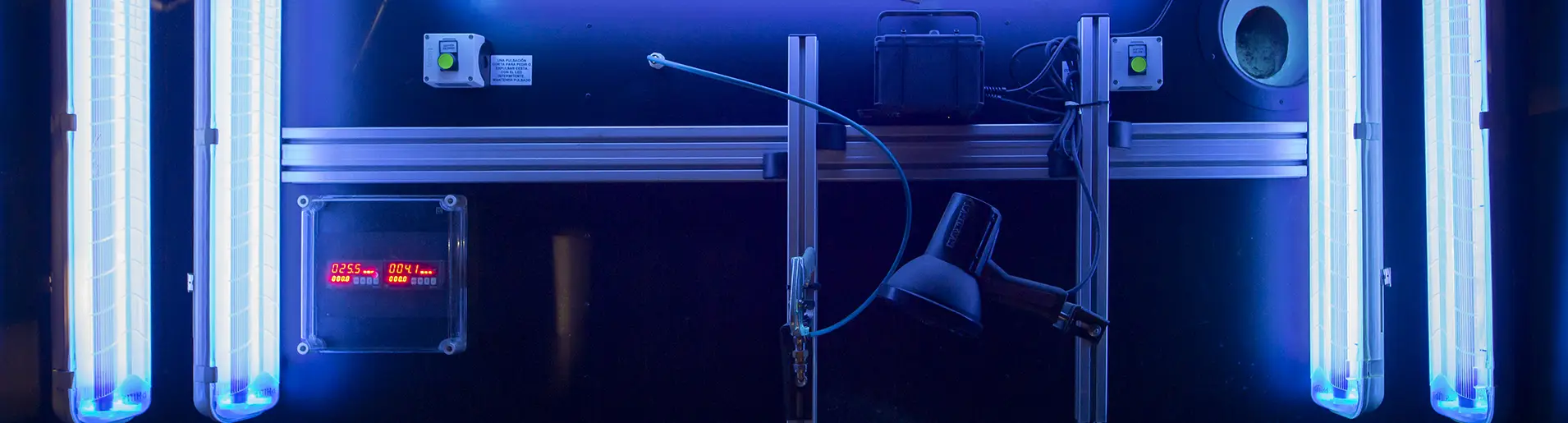

SURFACE TREATMENTS AND PROCESSES

SERVICES

© Electroless Hard Coat, S.A.